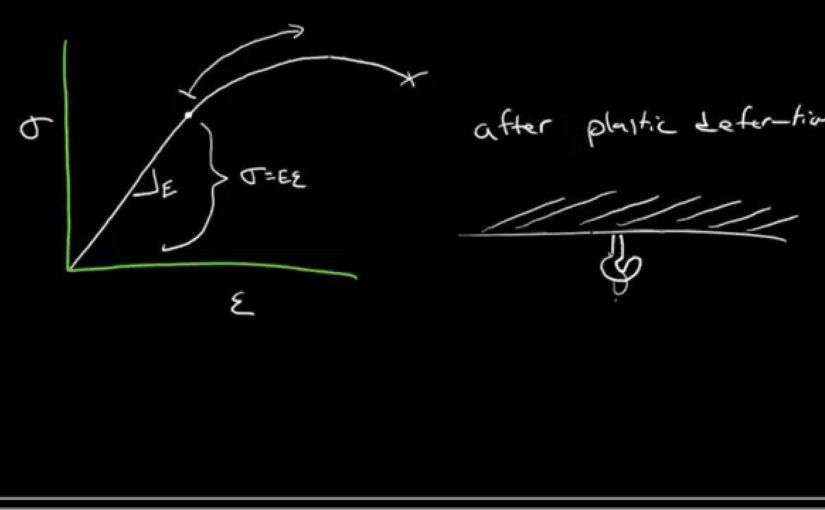

So we’ve sketched stress-strain. A curve like this

for typical metal. And we know an equation within

the linear elastic region. That’s before the

proportional limit. And that’s, of course,

Hooke’s Law– sigma equals E times epsilon. But what do we have after

plastic deformation? How can we perform calculations

after plastic deformation? If, for example,

we had something that– a bolt in

the ceiling– oh, that’s a horrendous drawing. Let’s fix that. Let’s fix that

before I lose my job. So here’s– that’s even worse. Oh, my goodness. OK. This is good. No, that’s still awful. But there’s a hook

and, I don’t know, something is hanging from it. I was going to draw

a force so I don’t have to draw something else. There’s a hook hanging

from the ceiling and you apply a

force to it and you want to know,

well, how much does that tie– that’s

what that is– it’s called intention– that

tensile tie– elongate? What’s its distance? What’s its length? And, well, you can only, at this point, do calculations

if the force results in a stress that’s

less than the yield strength. If it’s more than that, while

it’s classically deformed, we couldn’t deal

with it unless we had some kind of

way of describing the shape of the

curve after it leaves the linear elastic region. And it’s nice. We do have an

equation that fits the curve. But it’s going– we can’t

use engineering stress. We have to use what’s

called true stress. So that’s what I’d like to

introduce to you right now. So again, we’re going to take

a look at a generalized sample here. And the idea– the

goal– is of course that we’re going to go to

be able to this– calculate and understand

plastic deformation. So here’s our sample with its

initial cross-sectional area as we’ve discussed before. And we said, well,

when you load it, it gets longer

and gets narrower. And it’s that reduction in

the cross-sectional area that we’re interested in. This area here now, we could

call it an instantaneous area. Whereas this area, the white

one, was the initial area. The initial area was

what we started with. But then while the load

is applied– sorry, let me draw the force in. While the load is applied,

the cross-sectional area has decreased. So the first thing

you could do is we could say, all right, well, that

means that this material itself is experiencing a

force over a smaller area. So we could define

the true stress as the force over that

actual cross-sectional area. This is the true stress. This is the stress that

the material itself is feeling. OK? And that subscript

I am telling us this is the instantaneous

cross-sectional area. Instantaneous. I can’t do more than one thing

at the same time. Instantaneous– I missed a

U– cross-sectional area. Instantaneous cross-sectional area. And I’ll show you

what the plot would look like in just a moment. We could also do the same

thing for the strain, although that’s going to be

just a little bit– require a little bit more thinking. The true strain has to

account for the fact that what we’re doing is we’re

applying a change in length. Right? We’re elongating it

over a certain length. The very first little

bit of elongation is elongation over l0. But then, after

that, the elongation is elongated over the

previous length which was l0 plus that little delta l.

And so if you do that

for infinitely small– infinitesimally small

changes in length, the way we would write that

is we’d have to say, the true strain, what we’re

doing is we’re integrating. We’re integrating those

infinitesimally small changes in length– that’s dl– by l

from l0– the initial length– to the instantaneous length. And so if we do that,

you find that you have ln of l instantaneous

minus length 0, which is ln of l instantaneous over l0. So we have another

equation there. I’ll put a box around that. So this is the true strain. True strain. And if we take that true

stress and we plot it against the true strain,

I’ll show you what we get. Let me just

plot stress and strain and I’ll show you what

we’ve already seen. That’s the engineering

stress-strain curve. And then what I’ll do is I’ll

plot for you– after it starts to plastically deform the–

ran out of space there– the true stress– so this one

here– continues to increase. It doesn’t have that

decrease at the UTS. That’s the true stress

true strain curve. And this one is, of

course, engineering. The nice thing

about this plot is once you’ve got true

stress and true strain, we can fit that data

quite nicely for most metals with a simple equation. And that is true stress

is equal to this coefficient times the true strain

raised to the power n. So that’s an equation that fits

that true stress true strain data quite nicely. And what’s useful about

this is these are constants. That’s the constant n– I’ll

define it for you in a moment– and this K is also a constant. Those are material properties. We can look those up in

an engineering handbook. So n is called the–

well, this equation is called the

strain-hardening equation. Strain hardening equation. And strain hardening– hardening

correlates to– hardness correlates to strength. So really this is

the equation that’s telling us that we’re

strengthening the material and we’ve got the

strain hardening exponent and the strain

hardening coefficient K.

As found on YouTubeExplaindio Agency Edition FREE Training How to Create Explainer Videos & SELL or RENT them! Join this FREE webinar | Work Less & Earn More With

Explaindio AGENCY EDITION

And so if you do that

for infinitely small– infinitesimally small

changes in length, the way we would write that

is we’d have to say, the true strain, what we’re

doing is we’re integrating. We’re integrating those

infinitesimally small changes in length– that’s dl– by l

from l0– the initial length– to the instantaneous length. And so if we do that,

you find that you have ln of l instantaneous

minus length 0, which is ln of l instantaneous over l0. So we have another

equation there. I’ll put a box around that. So this is the true strain. True strain. And if we take that true

stress and we plot it against the true strain,

I’ll show you what we get. Let me just

plot stress and strain and I’ll show you what

we’ve already seen. That’s the engineering

stress-strain curve. And then what I’ll do is I’ll

plot for you– after it starts to plastically deform the–

ran out of space there– the true stress– so this one

here– continues to increase. It doesn’t have that

decrease at the UTS. That’s the true stress

true strain curve. And this one is, of

course, engineering. The nice thing

about this plot is once you’ve got true

stress and true strain, we can fit that data

quite nicely for most metals with a simple equation. And that is true stress

is equal to this coefficient times the true strain

raised to the power n. So that’s an equation that fits

that true stress true strain data quite nicely. And what’s useful about

this is these are constants. That’s the constant n– I’ll

define it for you in a moment– and this K is also a constant. Those are material properties. We can look those up in

an engineering handbook. So n is called the–

well, this equation is called the

strain-hardening equation. Strain hardening equation. And strain hardening– hardening

correlates to– hardness correlates to strength. So really this is

the equation that’s telling us that we’re

strengthening the material and we’ve got the

strain hardening exponent and the strain

hardening coefficient K.

And so if you do that

for infinitely small– infinitesimally small

changes in length, the way we would write that

is we’d have to say, the true strain, what we’re

doing is we’re integrating. We’re integrating those

infinitesimally small changes in length– that’s dl– by l

from l0– the initial length– to the instantaneous length. And so if we do that,

you find that you have ln of l instantaneous

minus length 0, which is ln of l instantaneous over l0. So we have another

equation there. I’ll put a box around that. So this is the true strain. True strain. And if we take that true

stress and we plot it against the true strain,

I’ll show you what we get. Let me just

plot stress and strain and I’ll show you what

we’ve already seen. That’s the engineering

stress-strain curve. And then what I’ll do is I’ll

plot for you– after it starts to plastically deform the–

ran out of space there– the true stress– so this one

here– continues to increase. It doesn’t have that

decrease at the UTS. That’s the true stress

true strain curve. And this one is, of

course, engineering. The nice thing

about this plot is once you’ve got true

stress and true strain, we can fit that data

quite nicely for most metals with a simple equation. And that is true stress

is equal to this coefficient times the true strain

raised to the power n. So that’s an equation that fits

that true stress true strain data quite nicely. And what’s useful about

this is these are constants. That’s the constant n– I’ll

define it for you in a moment– and this K is also a constant. Those are material properties. We can look those up in

an engineering handbook. So n is called the–

well, this equation is called the

strain-hardening equation. Strain hardening equation. And strain hardening– hardening

correlates to– hardness correlates to strength. So really this is

the equation that’s telling us that we’re

strengthening the material and we’ve got the

strain hardening exponent and the strain

hardening coefficient K.