There are

a few other things that we can determine

from the stress-strain curve of metal that

is quite interesting. And I’d like to just spend

a moment looking at that. So again, we’ve got

the stress here, on the vertical axis,

strain– typical metal. We have a curve that

looks something like this. It comes up looking linear

elastic, plastic, ultimate tensile strength,

and then fracture. And so we’ve determined

all of the strengths. We have the yield strength,

the ultimate tensile strength, and the fracture strength. But what other properties

can we determine? Well, first of all, one of them

that you may have heard about is the ductility. So ductility has a usage

in common language. You might say, well,

what’s ductility all about? If something’s very ductile,

you might say, well, it describes how much you

can stretch something. But of course, we

know that that’s not accurate enough. Stretch, is that referring

to elastic or plastic? So we’ve got to be

better than that. And in fact, I’ll

tell you ductility is a measure of a plastic strain. So we know

it’s a strain quantity, and it refers to plastic

deformation, only plastic strain to fracture. Now we’ve got something we

can work with– plastic strain to fracture. So let’s see well, this

is the point of fracture. That’s a fracture. So that fracture,

if we unload we’d have a value here

for total strain. Let me write that in there

for you, total strain. If we unloaded– if we

took the total strain there at fracture, just a moment

before it fractured, that would be our total strain. But what if we unloaded it? Somehow you knew just

infinitesimally before it was going to fracture– well,

we know that Young’s modulus is structure-independent. So it won’t change. So we would have unloaded

that same modulus. This means we come back down

here to a value on the strain axis, a finite value

corresponding to zero stress. It’s unloaded, there’s

no stress on it, but there’s still some

persistent strain. That strain has to be plastic. That’s a plastic strain, which

means that this strain here is elastic. That’s elastic, and that makes

sense because what is that? That’s the strain underneath

this linear unloading portion. And the unloading

portion, if it’s linear, is governed by Hooke’s law. And we know that’s elastic

because Hooke’s law refers to elastic behavior. So if we unload down and

we get plastic strain, that plastic strain has

got to be the ductility. So ductility, you

unload at fracture. And the remaining

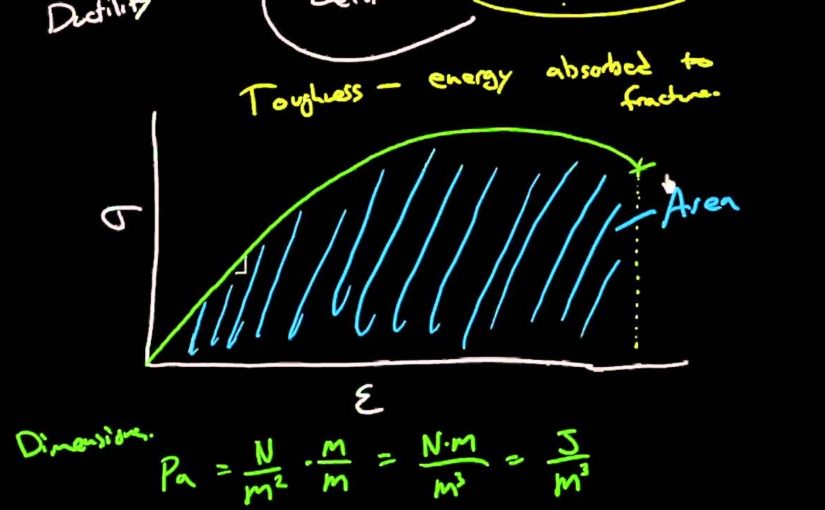

strain is the ductility. Another interesting property

that we can determine from this stress-strain

behavior for a metal, for other material classes as

well, is called toughness. And the toughness is sometimes

not such an intuitive quantity. You can understand strength,

it’s force over area. You got a sense for that. It’s pressure, if you will. Even modulus you can kind

of get a bit of an intuitive sense for it because

it’s how hard is it to bend

something elastically. It’s a little harder, but

the toughness is– toughness, I’ll tell you what the tough is. Toughness is the energy–

it’s an energy term. And it’s energy

absorbed to fracture. What we can do

is integrate. And that is to take the

area under the curve. So if we take the area

under this curve here, it would be this area here, all

this area here under the curve is the toughness.

And how do we know that? We could look at

it dimensionally. If we’re taking a product

of stress and strain and looking at the dimensions,

stress has units of Pascals. And what’s a Pascal? A Pascal is a Newton

per square meter. Well, I can go on living

my life multiplying whatever I want by 1 and just

multiply this screen by 1. You didn’t even notice. So here we go, where I multiply

Newton per square meter by 1, meter over meter, and I

end up with a familiar term in the numerator– Newton meter. And of course in the denominator

I’ve got volume units. But what’s the Newton meter? A Newton meter is

nothing more than a joule. So we’ve now got

joules per volume as units when we

integrate under this. And that’s great because

we want an energy unit. So if we integrate under the

entire curve up to fracture, it tells us how much energy

went into fracturing that. And that includes elastic

and plastic deformation. The final thing that we

can obtain from the stress curve, is

another energy unit and it’s quite useful– it’s

a stored energy unit this time. We’ve got stress and strain. We’ve got our linear elastic

region, plastic deformation, and fracture– is

the resilience. Thus resilience

is a measure of the stored elastic strain

energy at the yield strength. So again, we know if it’s going

to be an energy term, energy per volume for a given

volume of material, we’re going to have to

integrate under the curve. And where are we

going to do it from? Well, we’ll go to

the yield strength. And we go down from there. And if we unloaded at

the yield strength– I’m going to be a little

careful about something– if we unloaded at the

yield strength, you’d find that you have

a little sliver of permanent or plastic strain. Maybe it’s close to

the 0.2% offset strain. You’d probably have some plastic

strain accumulated when we had yield. For practical purposes, we say

it’s elastic before yielding and it’s plastic after. You might have a sliver. So we’re not going to

include that if we’re going to be strict with

our definition here. And so that area there

is the resilience. And that area is

just an area of a triangle. And we know that the

area of a triangle is 1/2 base times

height, which in our case is 1/2 of– well,

what’s the base? The base is the elastic strain. And that’s good because we’re

after the stored elastic strain energy. So we’ve got strain elastic. And what’s the height? Well, the height is

the yield strength. But we can, again,

do better than this. Because if it’s elastic,

it’s the area under this– or it’s the strain underneath

this linear unloading portion. And the linear

unloading portion, we have a mathematical

equation for. We have stress equals

E times strain. It’s a straight line. So that means that

the strain is going to be equal to sigma over

E. And we fire that in here, and we find that

the resilience is– I should erase that–

the resilience is going to be 1/2 of sigma,

and this is the sigma yield. That’s what we’re using here. So that’s sigma yield

over E times sigma yield. So at the end of the day, the

resilience, which we often use this– I’ll introduce

this symbol here. The full name for this

is the modulus of resilience. And modulus is just a fancy

word for a special number. So our special number here

is the modulus of resilience. And we use the

uppercase letter U. Is 1/2 sigma yield

squared upon E– and that’s an interesting

little equation. It tells you the stored

strain energy for a material. So if you’re going to make

a material for a spring, you’d look for something with

a high modulus of resilience. And again, the units

here, the dimensions here of modulus of

resilience are going to be joules per cubic meter.

As found on YouTubeExplaindio Agency Edition FREE Training How to Create Explainer Videos & SELL or RENT them! Join this FREE webinar | Work Less & Earn More With

Explaindio AGENCY EDITION

And how do we know that? We could look at

it dimensionally. If we’re taking a product

of stress and strain and looking at the dimensions,

stress has units of Pascals. And what’s a Pascal? A Pascal is a Newton

per square meter. Well, I can go on living

my life multiplying whatever I want by 1 and just

multiply this screen by 1. You didn’t even notice. So here we go, where I multiply

Newton per square meter by 1, meter over meter, and I

end up with a familiar term in the numerator– Newton meter. And of course in the denominator

I’ve got volume units. But what’s the Newton meter? A Newton meter is

nothing more than a joule. So we’ve now got

joules per volume as units when we

integrate under this. And that’s great because

we want an energy unit. So if we integrate under the

entire curve up to fracture, it tells us how much energy

went into fracturing that. And that includes elastic

and plastic deformation. The final thing that we

can obtain from the stress curve, is

another energy unit and it’s quite useful– it’s

a stored energy unit this time. We’ve got stress and strain. We’ve got our linear elastic

region, plastic deformation, and fracture– is

the resilience. Thus resilience

is a measure of the stored elastic strain

energy at the yield strength. So again, we know if it’s going

to be an energy term, energy per volume for a given

volume of material, we’re going to have to

integrate under the curve. And where are we

going to do it from? Well, we’ll go to

the yield strength. And we go down from there. And if we unloaded at

the yield strength– I’m going to be a little

careful about something– if we unloaded at the

yield strength, you’d find that you have

a little sliver of permanent or plastic strain. Maybe it’s close to

the 0.2% offset strain. You’d probably have some plastic

strain accumulated when we had yield. For practical purposes, we say

it’s elastic before yielding and it’s plastic after. You might have a sliver. So we’re not going to

include that if we’re going to be strict with

our definition here. And so that area there

is the resilience. And that area is

just an area of a triangle. And we know that the

area of a triangle is 1/2 base times

height, which in our case is 1/2 of– well,

what’s the base? The base is the elastic strain. And that’s good because we’re

after the stored elastic strain energy. So we’ve got strain elastic. And what’s the height? Well, the height is

the yield strength. But we can, again,

do better than this. Because if it’s elastic,

it’s the area under this– or it’s the strain underneath

this linear unloading portion. And the linear

unloading portion, we have a mathematical

equation for. We have stress equals

E times strain. It’s a straight line. So that means that

the strain is going to be equal to sigma over

E. And we fire that in here, and we find that

the resilience is– I should erase that–

the resilience is going to be 1/2 of sigma,

and this is the sigma yield. That’s what we’re using here. So that’s sigma yield

over E times sigma yield. So at the end of the day, the

resilience, which we often use this– I’ll introduce

this symbol here. The full name for this

is the modulus of resilience. And modulus is just a fancy

word for a special number. So our special number here

is the modulus of resilience. And we use the

uppercase letter U. Is 1/2 sigma yield

squared upon E– and that’s an interesting

little equation. It tells you the stored

strain energy for a material. So if you’re going to make

a material for a spring, you’d look for something with

a high modulus of resilience. And again, the units

here, the dimensions here of modulus of

resilience are going to be joules per cubic meter.As found on YouTubeExplaindio Agency Edition FREE Training How to Create Explainer Videos & SELL or RENT them! Join this FREE webinar | Work Less & Earn More With Explaindio AGENCY EDITION

And how do we know that? We could look at

it dimensionally. If we’re taking a product

of stress and strain and looking at the dimensions,

stress has units of Pascals. And what’s a Pascal? A Pascal is a Newton

per square meter. Well, I can go on living

my life multiplying whatever I want by 1 and just

multiply this screen by 1. You didn’t even notice. So here we go, where I multiply

Newton per square meter by 1, meter over meter, and I

end up with a familiar term in the numerator– Newton meter. And of course in the denominator

I’ve got volume units. But what’s the Newton meter? A Newton meter is

nothing more than a joule. So we’ve now got

joules per volume as units when we

integrate under this. And that’s great because

we want an energy unit. So if we integrate under the

entire curve up to fracture, it tells us how much energy

went into fracturing that. And that includes elastic

and plastic deformation. The final thing that we

can obtain from the stress curve, is

another energy unit and it’s quite useful– it’s

a stored energy unit this time. We’ve got stress and strain. We’ve got our linear elastic

region, plastic deformation, and fracture– is

the resilience. Thus resilience

is a measure of the stored elastic strain

energy at the yield strength. So again, we know if it’s going

to be an energy term, energy per volume for a given

volume of material, we’re going to have to

integrate under the curve. And where are we

going to do it from? Well, we’ll go to

the yield strength. And we go down from there. And if we unloaded at

the yield strength– I’m going to be a little

careful about something– if we unloaded at the

yield strength, you’d find that you have

a little sliver of permanent or plastic strain. Maybe it’s close to

the 0.2% offset strain. You’d probably have some plastic

strain accumulated when we had yield. For practical purposes, we say

it’s elastic before yielding and it’s plastic after. You might have a sliver. So we’re not going to

include that if we’re going to be strict with

our definition here. And so that area there

is the resilience. And that area is

just an area of a triangle. And we know that the

area of a triangle is 1/2 base times

height, which in our case is 1/2 of– well,

what’s the base? The base is the elastic strain. And that’s good because we’re

after the stored elastic strain energy. So we’ve got strain elastic. And what’s the height? Well, the height is

the yield strength. But we can, again,

do better than this. Because if it’s elastic,

it’s the area under this– or it’s the strain underneath

this linear unloading portion. And the linear

unloading portion, we have a mathematical

equation for. We have stress equals

E times strain. It’s a straight line. So that means that

the strain is going to be equal to sigma over

E. And we fire that in here, and we find that

the resilience is– I should erase that–

the resilience is going to be 1/2 of sigma,

and this is the sigma yield. That’s what we’re using here. So that’s sigma yield

over E times sigma yield. So at the end of the day, the

resilience, which we often use this– I’ll introduce

this symbol here. The full name for this

is the modulus of resilience. And modulus is just a fancy

word for a special number. So our special number here

is the modulus of resilience. And we use the

uppercase letter U. Is 1/2 sigma yield

squared upon E– and that’s an interesting

little equation. It tells you the stored

strain energy for a material. So if you’re going to make

a material for a spring, you’d look for something with

a high modulus of resilience. And again, the units

here, the dimensions here of modulus of

resilience are going to be joules per cubic meter.As found on YouTubeExplaindio Agency Edition FREE Training How to Create Explainer Videos & SELL or RENT them! Join this FREE webinar | Work Less & Earn More With Explaindio AGENCY EDITION