Description

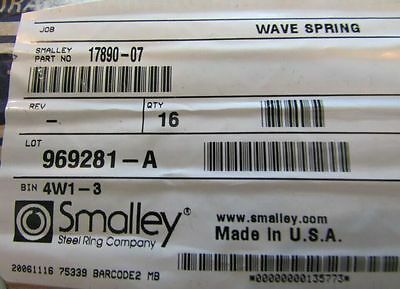

2282UC0C.06New Smalley Steel Crest-To-Crest Wave Springs, Flat Wire Springs, Part Number 17890-07. Each bid quantity is for a Lot of Two (2) Springs. You may bid / buy any number of lots, up to the total quantity available above.

These were purchased at an industrial liquidation earlier this year, and they were brand new in the original factory tubes. We repackaged them in heavy Ziplok bags for resale. Since these are in lots of two pieces, and since they try to get tangled with each other, we wrapped one piece in computer paper to help keep them separated.

We don’t know exactly what material these are made of, but they do attract a magnet. They are surprisingly strong for their appearance. We tested one by putting it on a set of digital scales, and it takes about (15) pounds to make it bottom out. You would think these things would go haywire when you put pressure on them. However, the coils stay perfectly stacked crest-to-crest, even without having them confined by a cylinder on the outside or a rod on the inside. In those situations, you could stack them almost indefinitely to obtain the desired amount of travel.

According to the calipers

Outside diameter: 2.047″

Inside diameter: 1.787″

Free height: 1-3/16″ (approx.)

Wire width: .125″ (1/8″)

Wire thickness: .013″

According to the manufacturer:

About Smalley Wave Springs

Compression Springs

Wave springs reduce spring height by 50%

Same force and deflection as ordinary coil / compression springs

Wave springs fit tight radial and axial spaces

Smalley Wave Springs (Flat Wire Compression Springs) offer the unique advantage of space savings when used to replace coil springs. By reducing spring operating height, wave springs also produce a decrease in the spring cavity. With a smaller assembly size and less material used in the manufacturing process, a cost savings is realized. Wave springs operate as load bearing devices. They take up play and compensate for dimensional variations within assemblies. A virtually unlimited range of forces can be produced whereby loads build either gradually or abruptly to reach a predetermined working height. This establishes a precise spring rate in which load is proportional to deflection. Functional requirements are necessary for both dynamic and static spring applications. Special performance characteristics are individually built into each spring to satisfy a variety of precise operating conditions. Typically, a wave spring will occupy an extremely small area for the amount of work it performs. The use of this product is demanded, but not limited to tight axial and radial space constraints.

Crest-to-Crest® Wave Springs

(Flat Wire Compression Springs)

Crest-to-Crest Wave Springs are pre-stacked in series, decreasing the spring rate proportionally to the number of turns. Uses are typically applications requiring low-medium spring rates and large deflections with low-medium forces.

Among the major advantages, this design eliminates the need to keep the wave crests aligned. The need to use a key locating device, or to insert a shim between individual springs is not necessary. Because the spring is integrally formed, the wave peaks hold their configuration.

As a replacement for helical compression springs, Crest-to-Crest springs can develop similar forces, yet occupy one-half (1/2) or less the axial space. This allows for strict space constraints. Crest-to-Crest Wave Springs will maintain the same force and load specifications of a conventional round wire spring, but with the advantages of resultant lowered and compacted operating heights, free heights and solid heights.